Automotive Service 1 - SPRINGS

- Matt Howell

- Mar 2, 2020

- 1 min read

The springs allow the wheels to move up to absorb bumps in the road and reduce jolting, while the dampers prevent bouncing up and down.

Any spring, whether it’s a leaf, torsion or coil spring, must compensate for irregularities in the road surface, maintain the suspension system at a predetermined height and support added weight without excessive sagging.

3 TYPES OF SPRINGS:

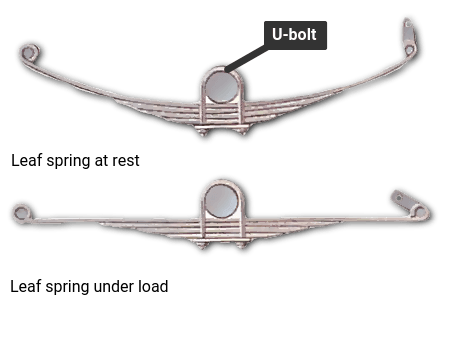

Leaf Springs

Historically speaking, the steel multi-leaf spring is one of the oldest and most widely used spring designs in suspension systems. The advantages of the leaf spring are many, not only because it acts as a spring, but also because it attaches the axle directly to the chassis.

See video of leaf spring in action: https://www.youtube.com/watch?v=7y6dz1tZQpc

Torsion Bar

The torsion bar is a length of spring steel with splined or square ends. One splined end is fixed to a lever arm that forms part of the suspension. The bar rotates as the lever arm moves up and down.

A torsion bar is of spring steel with one end rigidly fixed to the frame. The bar twists as the other end rotates with movements of the suspension lower arm.

The other splined end is fixed to the frame. The splines stop the bar turning in its fixings. Instead, the bar has to twist as the suspension deflects.

See video of Torsion Spring in action (0:30-1:00) : https://www.youtube.com/watch?v=LdbXzAr-NHw

Coil Springs

A coil spring is simply a spiral of resilient steel rod. It is stretched or compressed by the vertical movement of the wheels.

See video of Coil Spring in action: https://www.youtube.com/watch?v=CHJyVesMazc

Image credit & references:

Comments